Services

- HOME

- Services

Integrated in-house production from molding to firing and processing

Our company integrates ceramic production from processing to firing. We try to reduce post-firing polishing costs by thorough high-precision processing. We also realized greatly shortening the firing period by a designated furnace for 99.5%-authentic alumina.

We offer solutions to our clients, including prototyping, development, small-lot production from one piece, quality improvement and cost reduction by utilizing our accumulated expertise on ceramics processing.

Machining

NC Turning

Firing Ceramics

Target Materials: fine ceramics (alumina and zirconia, etc.)

Target Lots: 1 to A-few-thousand pieces (incl. prototypes)

Target Sizes: up to approx. 200mm (Consult for large units.) Delivery: in approx. 15 days (based on forms and volume)

Manufactured Items: semiconductor manufacturing equipment and industrial machine parts

Flow

Raw Materials

Spray Dry

Create Hydrostatic Pressure

Rubber Press (Dry and Wet)

Mechanical Press Forming

Grinding

Turning

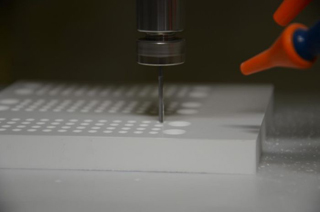

Detailed Processing and High-Precision Finish by M2screw, M2nut, φ0.15hole

Machining

600 holes per plate achieved

Firing(for 4 days)

Polishing

Inspection

Packing and Shipping